AI & Robotics: Tesla Optimus

Tesla Optimus is a general-purpose, two-legged humanoid robot developed by Tesla. It stands at approximately 173 cm tall and weighs around 57 kg. These dimensions make it comparable to an average human, allowing it to operate comfortably in both home and industrial environments. The robot can reach speeds of up to 8 km/h and carry loads of around 20 kg. Optimus is built with a lightweight frame, quiet electric actuators, and energy-efficient motors to ensure safe and stable performance.

Tesla states that the development of Optimus is based on the same AI architecture used in Tesla’s autonomous driving systems. This means that Optimus relies on camera-based perception and neural networks similar to those used in Tesla vehicles. As a result, the robot can navigate complex environments, recognize objects, and make real-time decisions. Its hand design includes multiple degrees of freedom for fine manipulation, allowing it to handle delicate tasks. The battery is designed to last through an entire workday during light to moderate activity. Safety remains a priority — the robot’s physical strength is intentionally limited to ensure safe interaction with humans.

Tesla’s Approach to Artificial Intelligence

With Optimus, Tesla aims to create a unified AI ecosystem connecting robotics and autonomous vehicles. The company’s vision revolves around real-world AI: systems that learn from large-scale data and adapt to unpredictable environments. Optimus is trained using massive datasets collected from Tesla cars, giving it a unique advantage — access to incredibly diverse real-world scenarios.

Tesla uses the same Full Self-Driving (FSD) hardware, computer vision system, and neural network planning logic inside both its cars and Optimus. This allows the robot to understand spatial environments in a human-like way. By reusing Tesla’s large-scale AI infrastructure and hardware, the company can reduce production costs and accelerate robot development, making Optimus a future candidate for mass production — not just a laboratory prototype.

Human-Robot Interaction

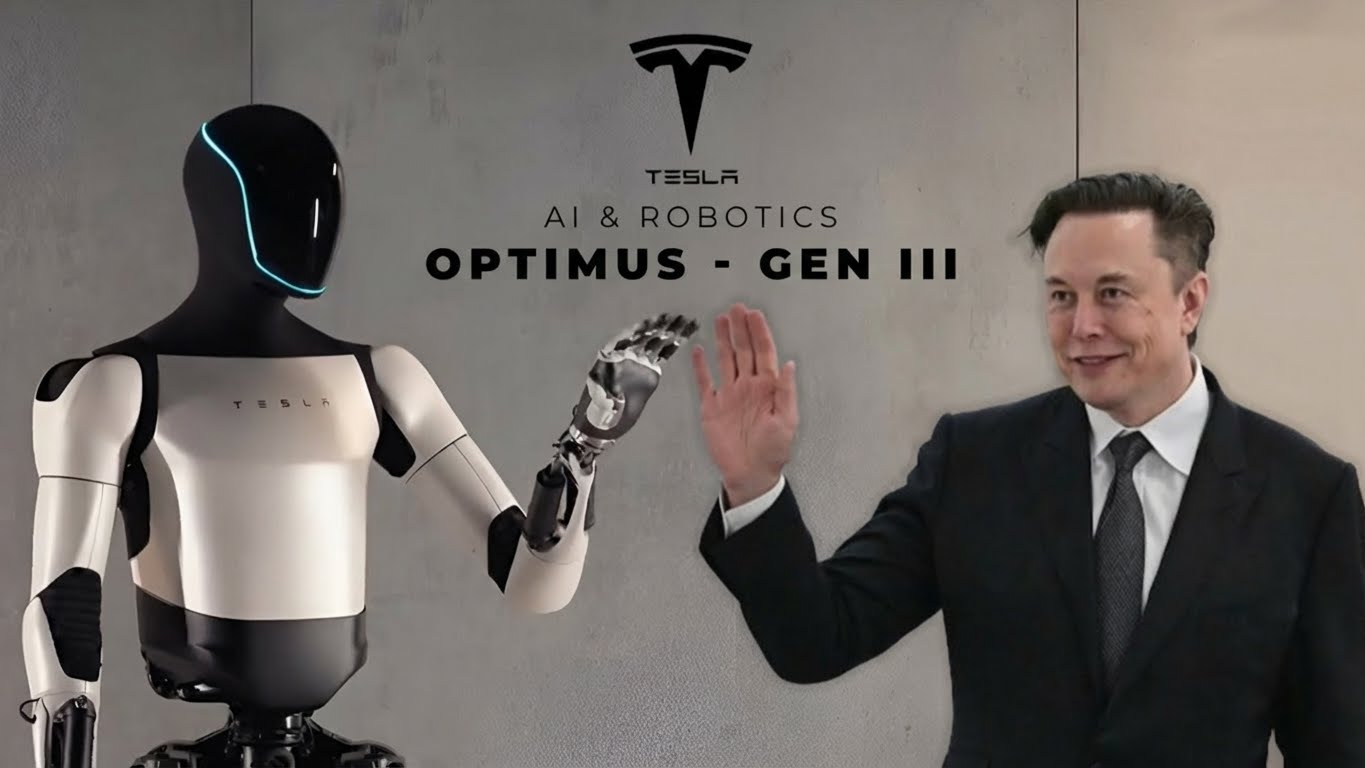

Optimus is designed to be a safe and friendly assistant. According to Tesla, the robot will focus on “boring, repetitive, and dangerous” tasks humans prefer to avoid. To ensure safety, the robot’s physical force is intentionally restricted so that a human can overpower it if necessary. This safety-first design philosophy aims to ensure comfortable and predictable interaction between humans and robots.

Optimus is also being developed with natural gestures, smooth motion and expressive animations to make human-robot communication more intuitive. In early demonstrations, the robot performs simple routines such as handing objects to humans, reacting to commands, and mimicking certain human movements. Such interactions mark the early stages of creating robots that can coexist with people in everyday environments.

Daily Life Applications of Optimus

The purpose of Optimus is to serve as an assistant in both personal and industrial settings. Potential household uses include:

- Clothing organization: folding clothes and arranging wardrobes

- Carrying groceries: transporting bags and organizing items

- Assisting with simple cooking tasks: stirring, preparing ingredients

- Cleaning: vacuuming, wiping surfaces, and general tidying

- Assistance for elderly or disabled individuals: supporting mobility and handling basic tasks

Beyond household use, Optimus has strong potential for light industrial work such as material transport, packaging, and repetitive assembly tasks. Tesla plans to test Optimus inside its own factories first, focusing on routine and repetitive activities that do not require complex human judgment.

If widely adopted, Optimus could significantly reduce the human workload in physically demanding or monotonous jobs, improving workplace safety and efficiency.

How Optimus Differs from Competitors

Several companies have begun building humanoid robots, and lightweight models already exist in China, the U.S., and Europe. Some competing robots focus on highly realistic human-like appearances or specialized bionic skin to create softer, friendlier interactions. Others focus on warehouse productivity or tele-operation for remote tasks. China’s IRON named humanoid robot of Xpeng company is one of the main competitor of Optimus robots.

Tesla’s key advantage lies in its mass-production strategy. While many humanoid robots currently cost hundreds of thousands of dollars and exist only as prototypes, Tesla intends to manufacture Optimus using the same production lines, hardware architecture, and supply chain used for its electric vehicles. This dramatically reduces cost and makes Optimus a candidate for large-scale adoption in homes and businesses.

Another core differentiator is Tesla’s AI approach: Optimus uses the same real-world driving data, neural networks, and planning logic as Tesla vehicles. This gives it a more mature and tested AI ecosystem than most young robotics startups.

Future Perspectives

The future of Optimus is ambitious. Tesla plans to begin limited production soon, with significant scaling in the following years. The projected price is estimated to be around the cost of 30,000 U.S Dollars, making it far more accessible than traditional industrial robots.

Optimus’ long-term impact could be profound: it may reshape labor markets, reduce human exposure to dangerous environments, and redefine everyday productivity. Some future-looking ideas include using Optimus in space missions, hazardous zones, or tasks requiring long-term endurance without fatigue.

As development continues, the line between human capability and robotic assistance will become increasingly seamless. Tesla Optimus represents not only a technological milestone but also the beginning of a new era where intelligent robots may become a part of our daily lives.